Liquefied natural gas is a low-temperature gas with a temperature of minus 162 degrees Celsius. In LNG storage tanks, it is inevitable to produce BOG (Boil off Gas) flash gas. The function of a BOG compressor is to process and recover flash steam and evaporative gas.

Atlas Copco Gas and Process Department specially designs a motor driven, one-stage and six stage compression centrifugal compressor that meets the process requirements of the second phase of the coal to natural gas project of Inner Mongolia Huineng Coal Chemical Co., Ltd., which compresses and transmits BOG gas to the recondenser, turns it into liquid again, and then recovers it to the storage tank. The centrifugal compressor is driven by a speed increasing gear set, which adopts a low-noise single spiral spur gear. The motor drives the rotation of each stage of the impeller through the large gear shaft of the gearbox. The compressor is made of materials that meet low-temperature applications.

Most domestic BOG applications use piston compressors, and Inner Mongolia Huineng Coal Chemical Co., Ltd.'s coal to natural gas project phase I also uses piston compressors. Why is the centrifugal compressor from Atlas Copco Gas and Process Department accepted in Phase II?

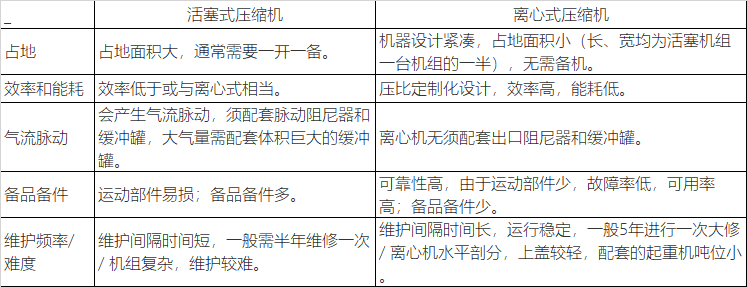

We can make a comparison: